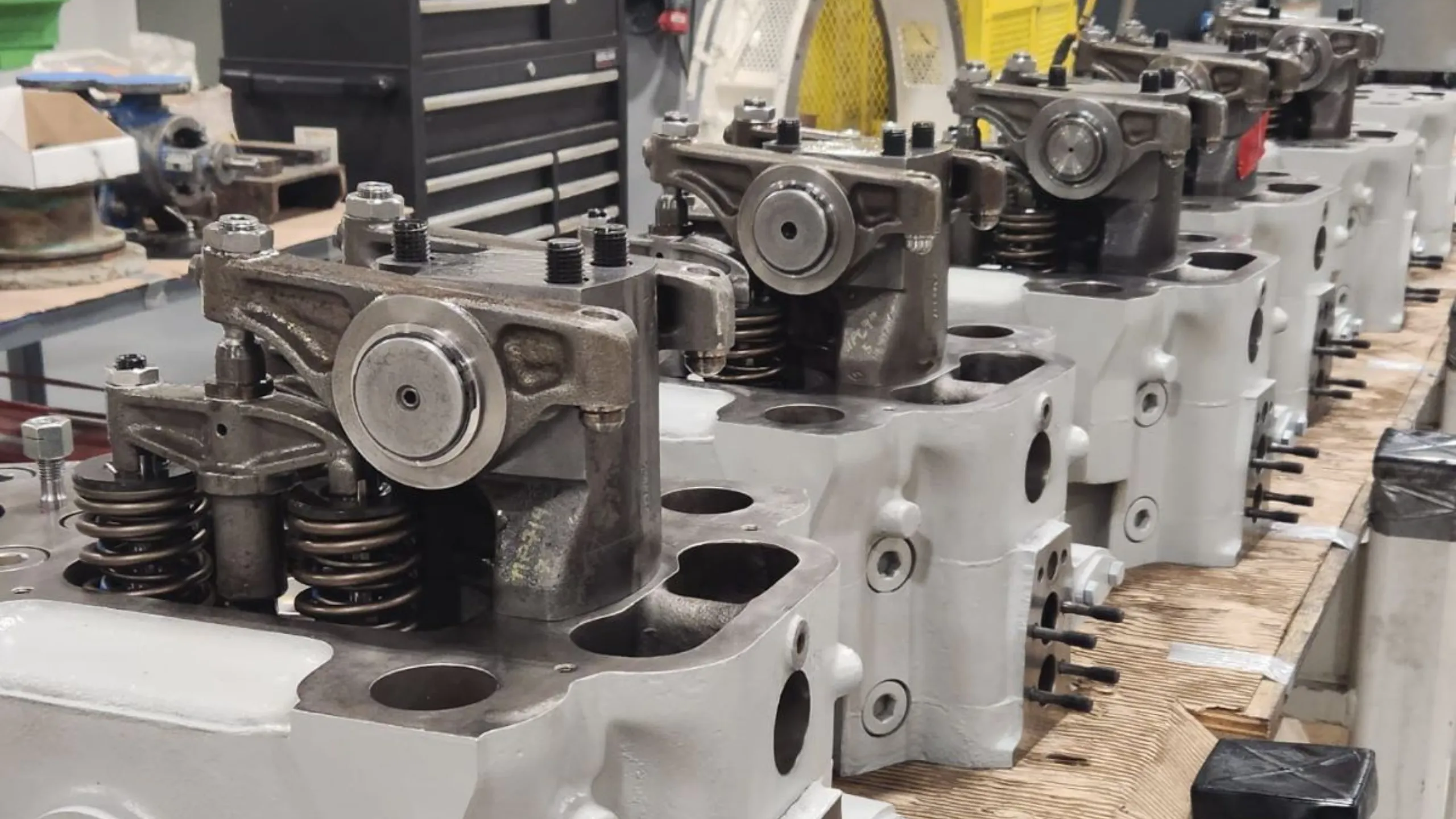

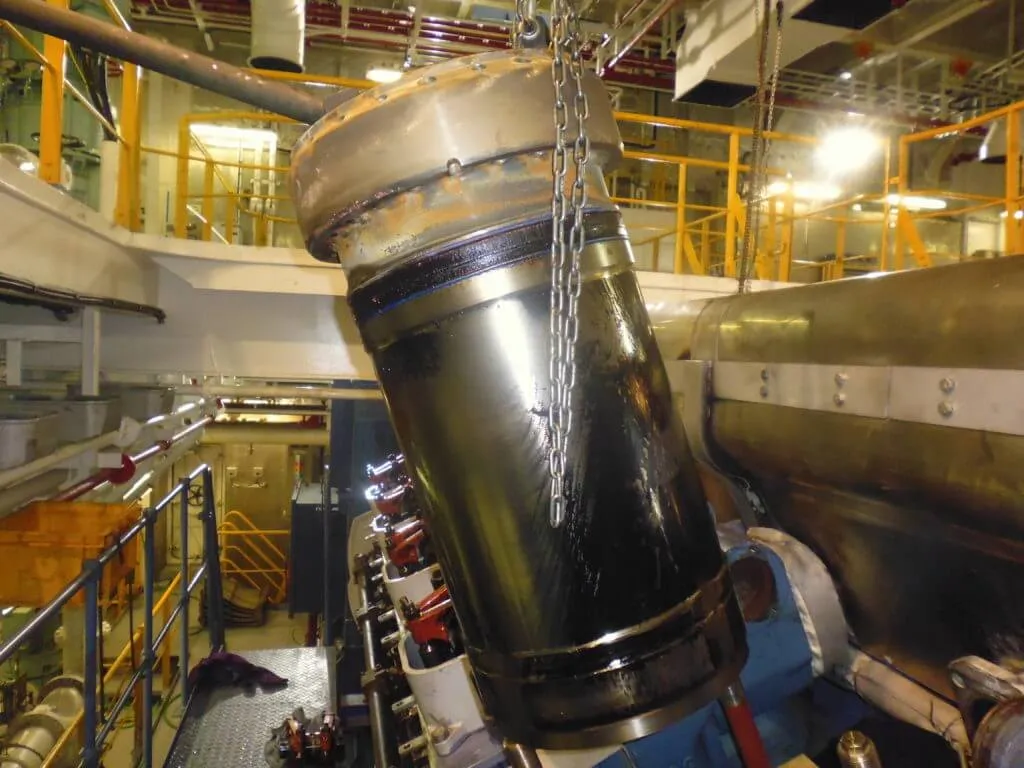

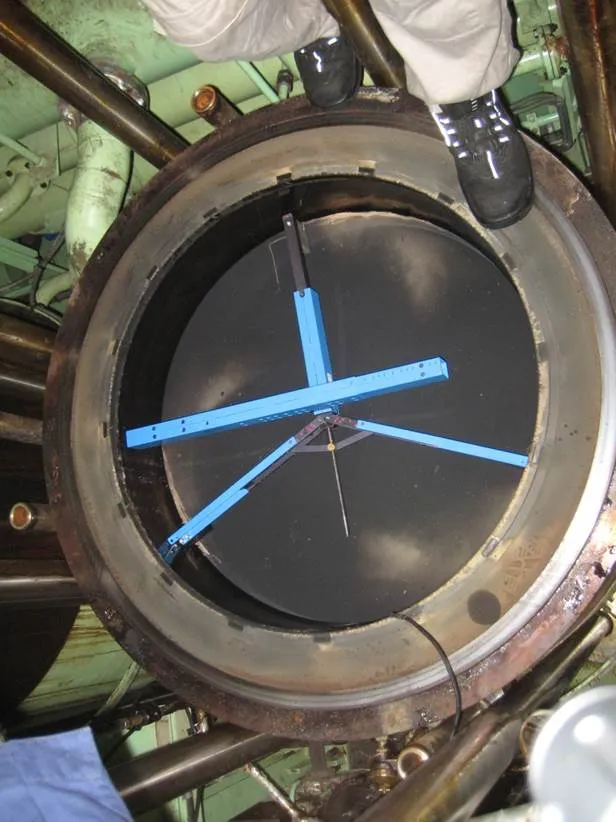

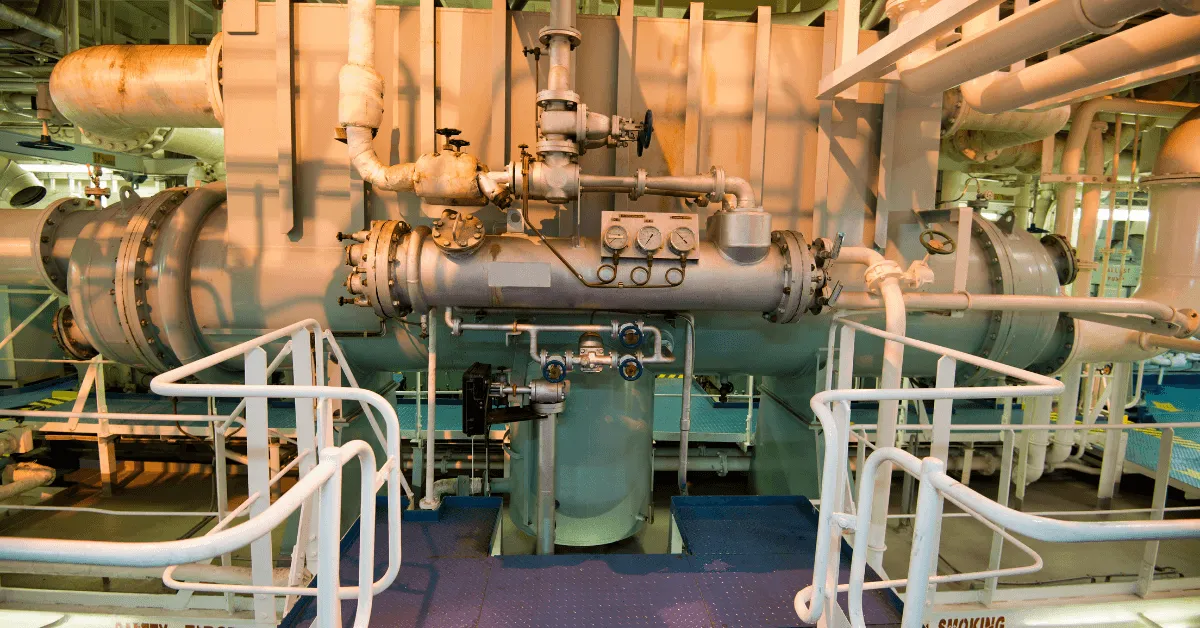

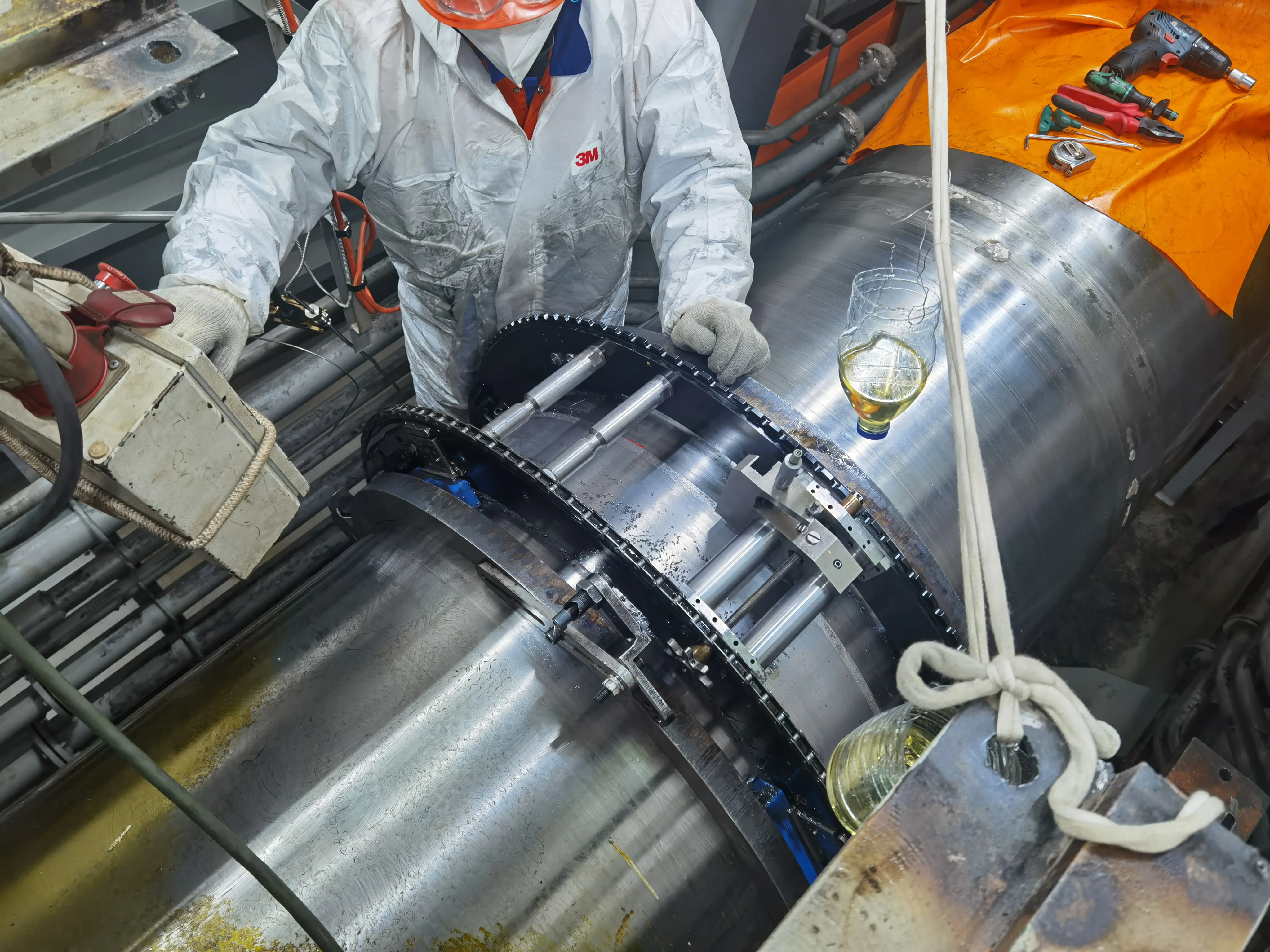

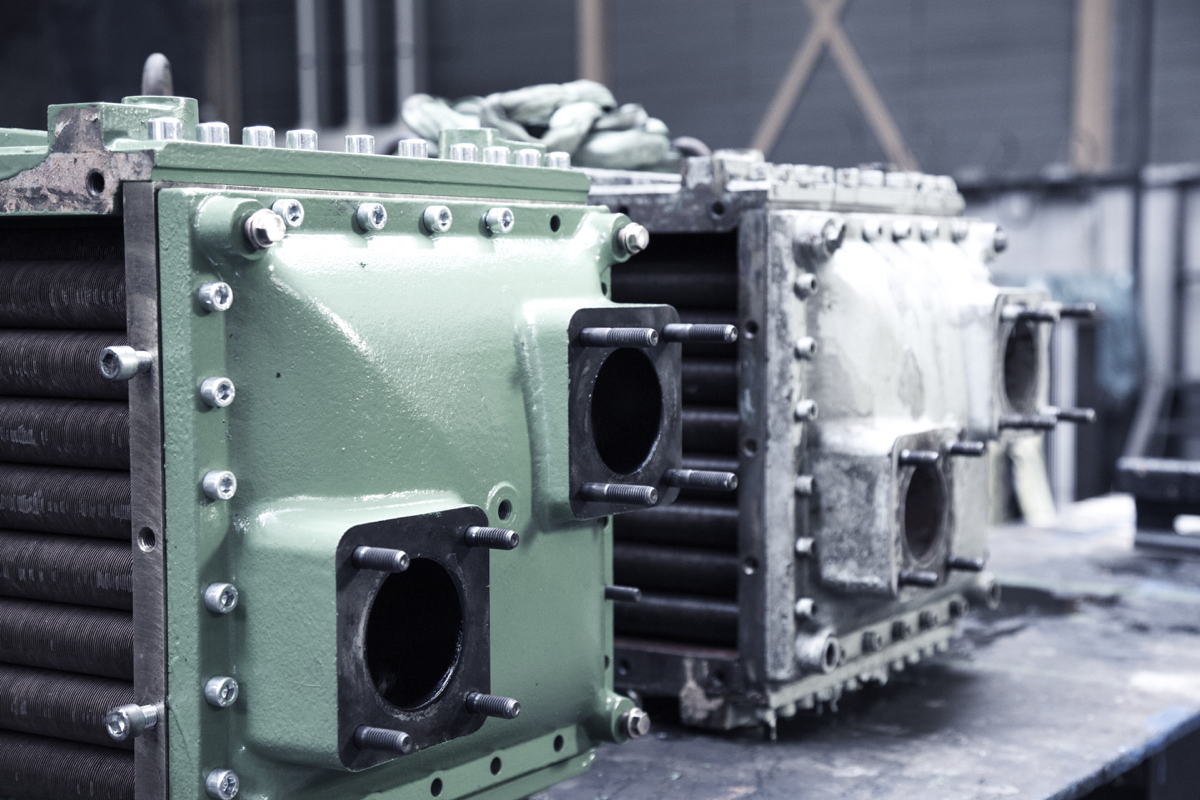

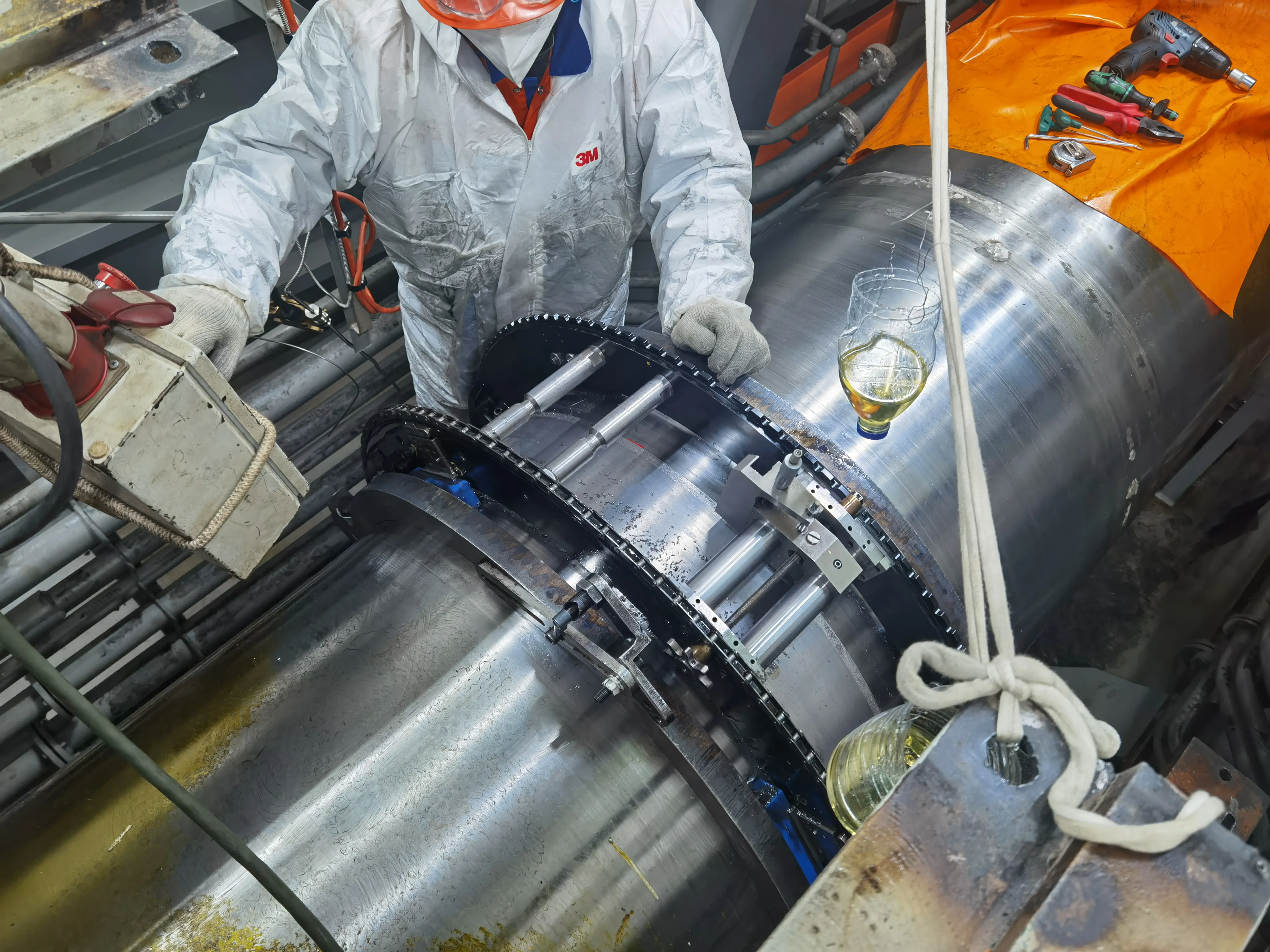

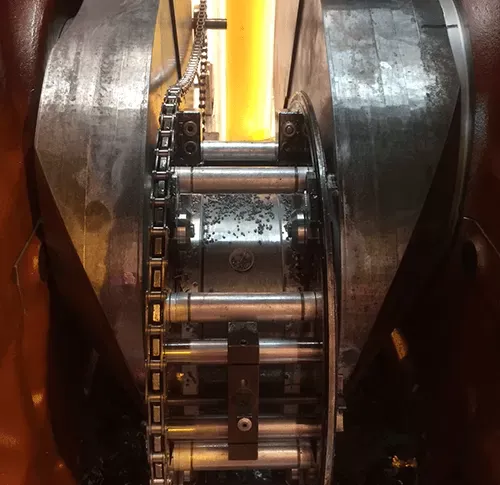

Troubleshooting and Diagnostics

Our expert troubleshooting services rapidly pinpoint the root causes of engine issues using advanced diagnostic tools, including vibration analysis, thermal imaging, and computerized fault scanning. We provide comprehensive reports and actionable solutions that minimize operational downtime and prevent costly repairs, ensuring your engines run safely and efficiently under all conditions.